English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

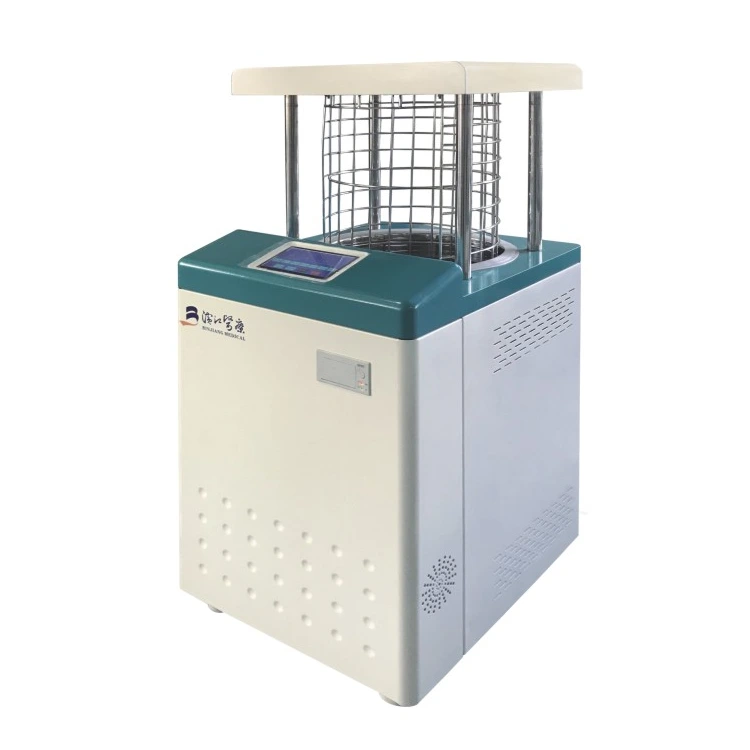

Vertical pulse vacuum steam sterilizer mushroom autoclave sterilization equipments

Vertical pulse vacuum steam sterilizer mushroom autoclave sterilization equipments Vertical pressure steam sterilizer mushroom autoclave sterilization equipments

Vertical pressure steam sterilizer mushroom autoclave sterilization equipments Horizontal pressure steam sterilizer autoclave for canning autoclave

Horizontal pressure steam sterilizer autoclave for canning autoclave Lcd Display Automation Sterilizer

Lcd Display Automation Sterilizer Led Display Automation Sterilizer

Led Display Automation Sterilizer- All new products

Pulse Vacuum Autoclave Lifting-door

Send Inquiry

WG series pulsating vacuum sterilizer uses saturated steam as the sterilization medium,which would completely penetrate into the surface of the articles through pulsating vacuum,and all the microorganisms and their spores would be killed by it under high pressure.It is the most reliable and effective method in physical sterilization.Pulsating vacuum exhaust eliminates the influence of cold air on temperature,finally the sterilizing articles are dried by vacuum dehumidification combined with jacket.

WG series pulsating vacuum sterilizer can be widely used in pharmaceutical,bioengineering,medical health,scientific research and other fields.It is applied to sterilizing the articles with high grade requirements,such as sterile clothes,medical cages,tools,instruments, rubber,liquid,medical dressing and so on.

Structure and Characteristic of the Equipment

● The Lifting door structure with removable-racks is motor chain driven with anti-pinch function,which guarantees more operation and installation space,is convenient for the loading and unloading for the articles.

● The two lifting doors are with pressure safety interlock,the liquid program is specially with temperature safety interlock.The two doors are interlocked.

● The inflation pressure drives the sealing ring to realize automatic sealing.The new high-quality high tear resistant silicone rubber circular hollow sealing ring has a special coating treatment on the surface,which is wear-resistant and smooth.It has better sealing effect and longer service life,with a service life of up to 1500 cycles.

● The main rectangular structure is with European ring type jacket with reinforcing ribs.The sealing groove is directly welded on the annular jacket at both ends(Getinge structure).

● Control system:Siemens PLC and color touch screen,the whole process is automatically controlled by program,and the operating process status,temperature,pressure,time and other parameters are automatically displayed.

● It is equipped with sterilization procedures such as sterile clothes,tools and instruments,rubber,liquid,culture medium,waste and custom procedures,as well as BD test,vacuum leakage test and other test procedures.

● The printer is optional,and it supports real-time data printing during the full process.

● Independent steam inlet design is optional for the customer,the steam would not pass through the jacket to avoid the pollution from the carton steel,and prevent the drying effected frm the jacket pressure drops.

● Pipeline system:stainless steel sanitary pipeline with clamp joints,are all welded by automatic pipe welder.German GEMUE angle seat valve,Taiwan Airtac solenoid valve,German SPECK direct-connected water ring vacuum pump.

● Water saving and noise reduction system(optional):Can reduce the circulating water consumption of vacuum pump by 30%and reduce the noise of vacuum pump.

● Automatic drain device(optional):Jacket automatic control drain device and inner chamber are equipped with automatic control drain device to automatically detect the temperature and pressure of jacket and inner chamber to drain automatically to ensure the saturation of steam.

● Low-temperature exhausting function(optional):drainage temperature≤55℃.

● Traceability system(optional):it has a communication interface connected with the quality traceability system of the disinfection supply center,and provides a software communication protocol connected with the traceability system.

● Intelligent maintenance system(optional):Equipped with remote monitoring and maintenance module,which can realize remote monitoring and remote software upgrading of equipment operation.

Main Parameters and Utilities

|

Designed Pressure of Inner Chamber |

-0.1~0.3MPa |

Opening Pressure for Inner Chamber's Safety Valve |

0.28MPa |

|

Designed Pressure of Jacket |

0.3MPa |

Opening Pressure for Jacket's Safety Valve |

0.28MPa |

|

Designed Temperature |

150℃ |

Precision of Sterilization Temperature Control |

0~2℃ |

|

Maximum Working Temperature |

138℃ |

Temperature Uniformity |

±1℃ |

|

Maximum Working Pressure |

0.25MPa |

Negative Pressure Pulsation Vacuum Amplitude and Times |

Amplitude-80~0KPa,Times 1~99 |

|

Vacuum Leakage Rate |

≤0.13KPa/min |

Times of Pulses Across Pressure |

Amplitude-80~80KPa,Times 1 |

|

Ultimate Vacuum |

-96KPa |

Times of Positive Pressure Pulses |

1~3 |

Size &Utilities

|

Model |

Size of Liner |

Volume (L) |

Overall Size L×W×H(mm) |

Weight (Kg) |

Steam Consumption (Kg/C) |

Power Supply |

Power |

|

|

W×H(mm) |

Depth(mm) |

|||||||

|

WG-0.15S(F) |

450×450 |

800 |

150 |

1160×1150×1820 |

550 |

12 |

380V,50HZ |

2KW+②KW |

|

WG-0.2S(F) |

450×450 |

1000 |

200 |

1360×1150×1820 |

750 |

15 |

380V,50HZ |

2KW+②KW |

|

WG-0.25 S(F) |

550×550 |

845 |

250 |

1195×1290×1900 |

850 |

18 |

380V,50HZ |

2KW+4KW |

|

WG-0.3S(F) |

550×550 |

1000 |

300 |

1350×1290×1900 |

950 |

18 |

380V,50HZ |

2KW+4KW |

|

WG-0.36 S(F) |

610×610 |

1000 |

360 |

1360×1350×1940 |

1050 |

22 |

380V,50HZ |

2KW+24KW |

|

WG-0.45S(F) |

652×700 |

1000 |

450 |

1360×1400×2060 |

1150 |

30 |

380V,50HZ |

2KW+36KW |

|

WG-0.6S(F) |

652×700 |

1320 |

600 |

1675×1400×2060 |

1250 |

36 |

380V,50HZ |

2KW+36KW |

|

WG-0.8S(F) |

652×700 |

1750 |

800 |

2105×1400×2060 |

1450 |

45 |

380V,50HZ |

2KW+48KW |

Note:②43648 represent the power of the built-in steam generator(optional)