English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Vertical pulse vacuum steam sterilizer mushroom autoclave sterilization equipments

Vertical pulse vacuum steam sterilizer mushroom autoclave sterilization equipments Vertical pressure steam sterilizer mushroom autoclave sterilization equipments

Vertical pressure steam sterilizer mushroom autoclave sterilization equipments Horizontal pressure steam sterilizer autoclave for canning autoclave

Horizontal pressure steam sterilizer autoclave for canning autoclave Lcd Display Automation Sterilizer

Lcd Display Automation Sterilizer Led Display Automation Sterilizer

Led Display Automation Sterilizer- All new products

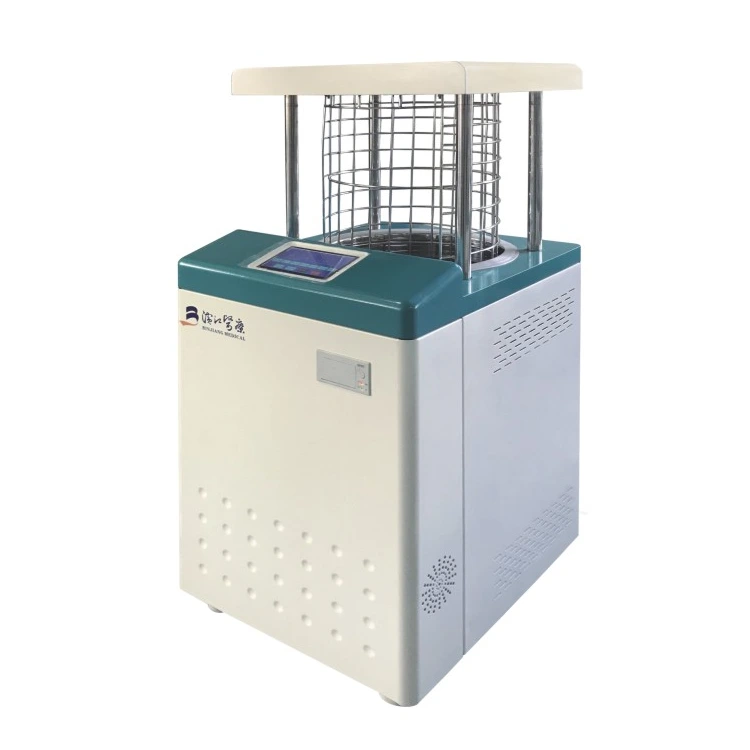

WG Series Pulse Vacuum Sterilizer

Send Inquiry

WG Series Pulse Vacuum Sterilizer

This series of WG Series Pulse Vacuum Sterilizer utilizes saturated steam as its sterilization medium which releases a large amount of heat in the stage of condensation, and ensure the sterilizing environment in high temperature and at a certain humidity.

After a period of insulation in such status, sterilization purpose is achieved. The application of pulsating vacuum exhausting has successfully eliminated the temperature influence from cold air, and helping the sterilization items to be dried by means of vacuum and dehumidification between the jacketed layers.

Structure and Characteristic of the WG Series Pulse Vacuum Sterilizer

Body of the sterilizer.

WG Series Pulse Vacuum Sterilizer is designed and manufactured in accordance with GB150 *the Pressure Vessel. GB8599 The Techniseal Requirements of Large Steam sterilizer-Automatic Control Protocol". and TSG Rt004 the -Safety and Technology Specification for Fixed Monitor VesseNi and related insertion procedures.

The chamber in horizontal rectangular shape with double layer structure is made from S3008.

Door sealing:Pneumatic scaling:Both doors are interlocked and completely conform to the requirements of the specification with standard GMP authentication interface.

Sterilizer piping system: the pipeline is designed with the best configuration. All the spares are from qualified brands at home and abroad.

Sterilizer control system: SIEMENS PLC and SIEMENS touch screen, this system is easy to implement the program selection, parameter setting equipment operation, report processing and other functions. WG Series Pulse Vacuum Sterilizer has prefect safety measures The FO value and the temperature time gives double guarantee for sterilization. A single parameter control is also available. WG Series Pulse Vacuum Sterilizer has prefect sterilization records.

Main Parameters and Utilities of WG Series Pulse Vacuum Sterilizer

|

Design Pressure |

0.245Mpa |

|

Working Pressure |

0.225Mpa |

|

Design Temperature |

139℃ |

|

Working Temperature |

105-134℃ |

|

Vacuum |

-0.09Mpa |

|

Temperature Equilibrium |

≤±1℃ |

|

Water Source Pressure |

0.15-0.3Mpa |

|

Compressed Air Pressure |

0.3-0.7Mpa |

|

Steam Pressure |

0.3-0.7Mpa |

|

Power |

AC380V, 50HZ |

Size & Utilities of WG Series Pulse Vacuum Sterilizer

Note: 2436 represent the power of the built-in steam generator (optional)

|

Model |

Overall Size L×W×H(mm) |

Chamber Size L×W×H(mm) |

Steam Consumption(KG) |

Tap Water Consumption(KG) |

Power(KW) |

Net Weight(KG) |

|

WG-0.25 |

1100×1350×1900 |

800×600×600 |

18KG |

35KG |

2+24KW |

900KG |

|

WG-0.36 |

1300×1350×1900 |

1000×600×600 |

25KG |

40KG |

2+24KW |

1000KG |

|

WG-0.6 |

1500×1360×1950 |

1200×610×910 |

30KG |

45KG |

3+36KW |

1400KG |

|

WG-0.8 |

1800×1360×1950 |

1500×610×910 |

40KG |

50KG |

3KW |

1600KG |

|

WG-1.2 |

1750×1440×1950 |

1450×680×1180 |

48KG |

55KG |

4KW |

1800KG |

|

WG-1.5 |

2150×1440×1950 |

1850×680×1180 |

55KG |

60KG |

4KW |

2000KG |

|

WG-2.0 |

1950×1750×2200 |

1600×900×1400 |

65KG |

65KG |

4.5KW |

2500KG |

|

WG-2.5 |

2300×1750×2200 |

1950×900×1400 |

75KG |

75KG |

6KW |

3000KG |

|

WG-3.0 |

2700×1750×2200 |

2400×900×1400 |

90KG |

90KG |

8KW |

3500KG |